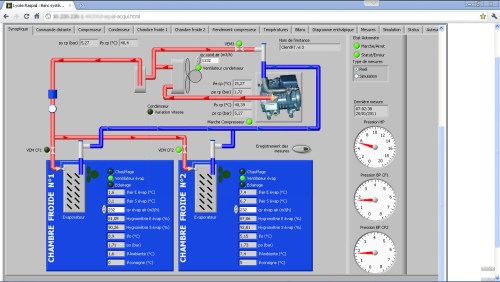

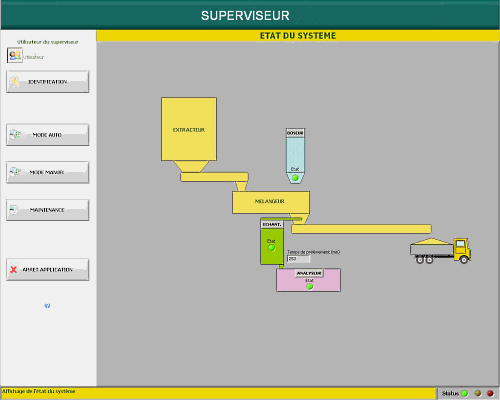

LabVIEW is a development environment specialized in industrial and scientific applications. Its uniqueness is that it relies on the G language, created by National Instruments, which is fully graphical. It can create complex software, while facilitating the programming and thus reduce development time. Through its library of functions for data acquisition, instrumentation, analysis of mathematical measures, but also through the rapid creation of GUIs and coding simplified, the engineer has more time to focus on specific functions of the instrumentation communication and measurement analysis. LabVIEW is particularly suitable for developing control, supervision, test and measurement systems.