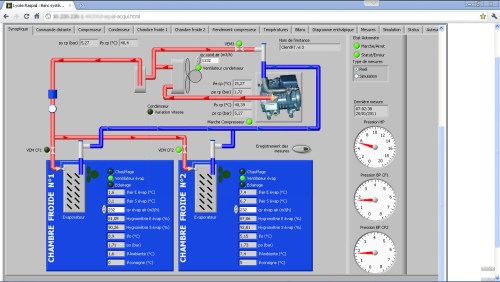

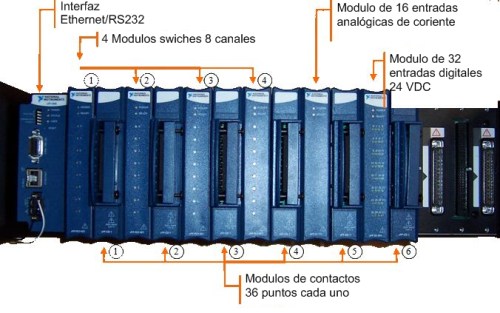

This system allows the study of refrigeration systems and the implementation of the thermodynamic calculations applied to refrigeration. Its uniqueness is that it is fully controllable via the Internet directly from a web browser like Internet Explorer or Firefox. It consists of two cold rooms, each with their own evaporator but sharing the same cooling fluid R134a system (compressor, condenser ...). The control and configuration of this system can be done in two ways: a classic console coupled to a regulator PLC type industrial PAC (programmable automation controller) Compact Fieldpoint The Compact Fieldpoint adds the possibility of remote control via the Internet, viewing the evolution curves of temperature, air and refrigerant fluid, pressure and power at various points. This allows calculating the required cooling system features such as enthalpy, entropy, Mollier diagram and performance coefficients. Refrigeration system with control panel and circuit fluid Hardware The software is embedded in a Compact Fieldpoint controller from National Instruments. It includes a RJ45 Ethernet connector that allows to connect to the